- 400-0510-786

- shenjia@keqiangtape.com

-

Mon - Fri: 9:00 - 19:00 / Closed on Weekends

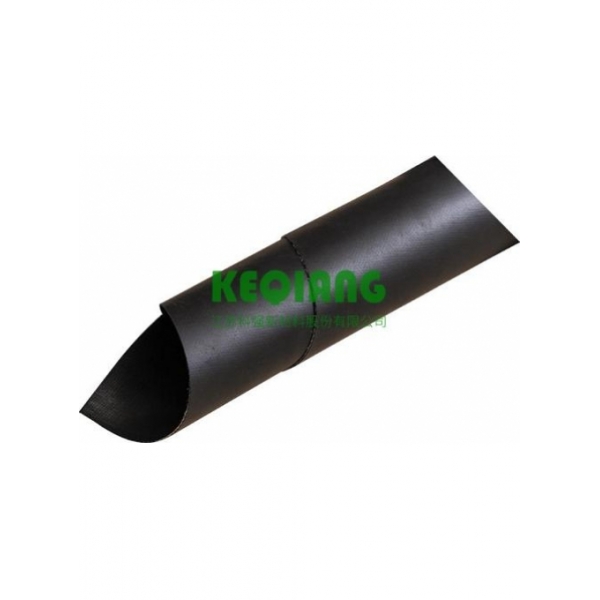

Gas tank rubber sealing film

- Direct supply from the manufacturer

- Whatsapp:+86 13812135827

- E-mail:shenjia@keqiangtape.com

Detail

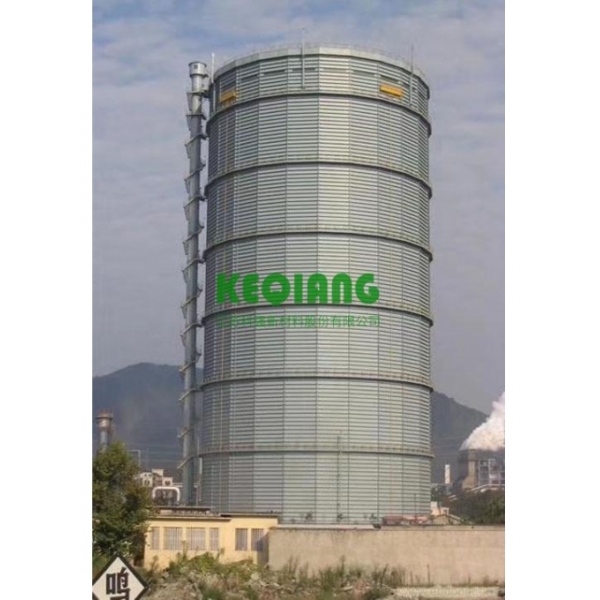

Product introduction gas tank rubber sealing film is the main sealing device on the Wiggins gas tank. It is one of the main factors that determine whether the gas tank can operate safely and the sealing effect is good or bad. Therefore, it occupies a very important position in the gas tank. Wiggins gas tanks are widely used to store gas in steel, city gas, petrochemical and other industries.

In view of the large volume of the gas tank rubber membrane products, the complex environment, and the dynamic conditions during use, the gas tank rubber sealing membrane must meet:

1) Load the weight in the vertical direction, must not be stretched or deformed, and have sufficient strength;

2) Appropriate tensile deformation properties in the can diameter direction;

3) Good flexibility;

4) Reliable air tightness;

5) Medium corrosion resistance, permeability resistance, ozone aging resistance, heat aging resistance;

6) It has a wide operating environment temperature.

Based on many years of experience in producing military, petroleum, chemical, and engineering construction tape products, our company has cooperated with military scientific research institutions to conduct a large number of comparisons and analyses of various performance indicators of gas tank rubber sealing membrane products produced at home and abroad. On the basis of the requirements and suggestions of the users, we will actively innovate and make breakthroughs. The performance indicators of the gas tank rubber sealing film produced by our company basically meet or exceed similar products at home and abroad. Product features Frame mechanism and materials Since the gas tank rubber sealing film is a large-scale tape product, the selection of the frame material is very important. In order to meet the requirements that the product bears weight in the vertical direction, must not be stretched and deformed, and has sufficient strength, and has an appropriate amount of tensile deformation performance in the radial direction, our company adopts the "m"-shaped three-layer structure on the skeleton structure. The mechanism enables the product to achieve the high strength requirements in the 45° angle direction from the left and right, overcomes the tensile deformation in the vertical direction, has sufficient strength, and at the same time has good flexibility and flexibility. The frame material adopts cord fabric to ensure the strength requirements of the product. Hot-pressing vulcanization splicing machine (21 meters in length) The formula and materials of the gas tank rubber sealing film can have good air tightness, ozone resistance, hydrogen sulfide gas corrosion resistance, aromatic hydrocarbon solvent resistance, mainly depends on the type of rubber and The formula of the rubber compound. At present, the main materials at home and abroad mainly use nitrile rubber + polyvinyl chloride (PVC), but the same formula and different production processes have far It was well received.

In order to further meet the flexibility requirements of the rubber sealing film of the gas tank and improve the adhesion between the skeleton material and the rubber, we have selected the auxiliary materials used in the military products; at the same time, the unique *plastic auxiliary materials are selected to achieve a wider range of products. Use environmental temperature requirements.

In the combination of materials, we research and develop according to the characteristics of the southern and coastal climate and environment, so that the products have good acid and alkali resistance and mold resistance. Super-large calender (width 3.8 meters) Production process Our company uses a four-roll calender for double-sided rubber rubbing in the rubber rubbing process, which improves the adhesion of the rubber and the fabric and ensures the strength and flex resistance of the fabric.

Our company uses a 3.8-meter-wide super large continuous vulcanization production line. The length of the vulcanized product is unlimited. The single width of the gas tank rubber sealing film produced is 3.6 meters, which reduces the number of seams in the radial direction. The general width of the single rubber curtain of the cabinet rubber sealing film is 1.2m.

3.8 meters wide super large continuous vulcanization production line is the key equipment in the life cycle of the gas tank rubber sealing film production process, which can guarantee to meet the customer's supply cycle.

Bonding and molding process Our company uses a 21-meter-long flat vulcanizing machine to form the entire bonding seam at one time to ensure the product's bonding strength and dimensional stability. Sealing film installation site

Quality assurance and testing Our company passed the ISO9001* quality management system certification in 2006. Continuous improvement and improvement of product quality are our eternal pursuit.

Our company has the most advanced testing equipment, with perfect testing methods, and each performance can be self-tested. In order to ensure the air tightness of the rubber sealing film of the gas tank, our company has produced a special testing equipment to test each bonding seam.

In view of the large volume of the gas tank rubber membrane products, the complex environment, and the dynamic conditions during use, the gas tank rubber sealing membrane must meet:

1) Load the weight in the vertical direction, must not be stretched or deformed, and have sufficient strength;

2) Appropriate tensile deformation properties in the can diameter direction;

3) Good flexibility;

4) Reliable air tightness;

5) Medium corrosion resistance, permeability resistance, ozone aging resistance, heat aging resistance;

6) It has a wide operating environment temperature.

Based on many years of experience in producing military, petroleum, chemical, and engineering construction tape products, our company has cooperated with military scientific research institutions to conduct a large number of comparisons and analyses of various performance indicators of gas tank rubber sealing membrane products produced at home and abroad. On the basis of the requirements and suggestions of the users, we will actively innovate and make breakthroughs. The performance indicators of the gas tank rubber sealing film produced by our company basically meet or exceed similar products at home and abroad. Product features Frame mechanism and materials Since the gas tank rubber sealing film is a large-scale tape product, the selection of the frame material is very important. In order to meet the requirements that the product bears weight in the vertical direction, must not be stretched and deformed, and has sufficient strength, and has an appropriate amount of tensile deformation performance in the radial direction, our company adopts the "m"-shaped three-layer structure on the skeleton structure. The mechanism enables the product to achieve the high strength requirements in the 45° angle direction from the left and right, overcomes the tensile deformation in the vertical direction, has sufficient strength, and at the same time has good flexibility and flexibility. The frame material adopts cord fabric to ensure the strength requirements of the product. Hot-pressing vulcanization splicing machine (21 meters in length) The formula and materials of the gas tank rubber sealing film can have good air tightness, ozone resistance, hydrogen sulfide gas corrosion resistance, aromatic hydrocarbon solvent resistance, mainly depends on the type of rubber and The formula of the rubber compound. At present, the main materials at home and abroad mainly use nitrile rubber + polyvinyl chloride (PVC), but the same formula and different production processes have far It was well received.

In order to further meet the flexibility requirements of the rubber sealing film of the gas tank and improve the adhesion between the skeleton material and the rubber, we have selected the auxiliary materials used in the military products; at the same time, the unique *plastic auxiliary materials are selected to achieve a wider range of products. Use environmental temperature requirements.

In the combination of materials, we research and develop according to the characteristics of the southern and coastal climate and environment, so that the products have good acid and alkali resistance and mold resistance. Super-large calender (width 3.8 meters) Production process Our company uses a four-roll calender for double-sided rubber rubbing in the rubber rubbing process, which improves the adhesion of the rubber and the fabric and ensures the strength and flex resistance of the fabric.

Our company uses a 3.8-meter-wide super large continuous vulcanization production line. The length of the vulcanized product is unlimited. The single width of the gas tank rubber sealing film produced is 3.6 meters, which reduces the number of seams in the radial direction. The general width of the single rubber curtain of the cabinet rubber sealing film is 1.2m.

3.8 meters wide super large continuous vulcanization production line is the key equipment in the life cycle of the gas tank rubber sealing film production process, which can guarantee to meet the customer's supply cycle.

Bonding and molding process Our company uses a 21-meter-long flat vulcanizing machine to form the entire bonding seam at one time to ensure the product's bonding strength and dimensional stability. Sealing film installation site

Quality assurance and testing Our company passed the ISO9001* quality management system certification in 2006. Continuous improvement and improvement of product quality are our eternal pursuit.

Our company has the most advanced testing equipment, with perfect testing methods, and each performance can be self-tested. In order to ensure the air tightness of the rubber sealing film of the gas tank, our company has produced a special testing equipment to test each bonding seam.

If you have any questions or comments, you can leave us a message and we will reply to you as soon as possible