- 400-0510-786

- shenjia@keqiangtape.com

-

Mon - Fri: 9:00 - 19:00 / Closed on Weekends

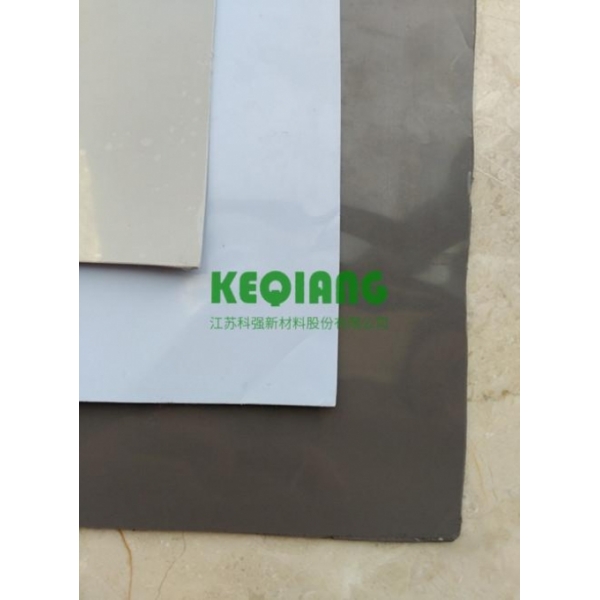

Thermally conductive silicone sheet

- Direct supply from the manufacturer

- Whatsapp:+86 13812135827

- E-mail:shenjia@keqiangtape.com

Detail

Thermally conductive silicone sheet

"Thermal conductive silicone sheet" is a kind of thermal conductive medium material synthesized by special process with silica gel as the base material and various auxiliary materials such as metal oxides. In the industry, it is also called thermal conductive silicone pad, thermal conductive silicone film, and soft. Thermally conductive pads, thermally conductive silicone gaskets, etc., are specially produced for the design of using gaps to transfer heat. They can fill the gaps and complete the heat transfer between the heating part and the heat dissipation part. At the same time, it also plays the role of insulation, shock absorption, and sealing. It can meet the design requirements of equipment miniaturization and ultra-thinness. It is extremely manufacturable and usable, and has a wide range of thicknesses. It is an excellent thermally conductive filler material.

Advantages and disadvantages of thermally conductive silicone sheet

Advantages 1. The material is softer, the compression performance is good, the thermal insulation performance is good, the thickness adjustable range is relatively large, suitable for filling the cavity, the two sides have natural viscosity, operability and maintainability; 2, the use of thermally conductive silicone sheet* The main purpose is to reduce the thermal contact resistance between the surface of the heat source and the contact surface of the heat sink. The thermally conductive silicone sheet can fill the gap of the contact surface very well; Heat transfer between the heat source and the radiator, and the installation of a thermally conductive silicone sheet between the heat source and the radiator can squeeze the air out of the contact surface; 4. With the supplement of the thermally conductive silicone sheet, the contact surface between the heat source and the radiator can be better The full contact, truly face-to-face contact. The reaction in temperature can achieve the smallest possible temperature difference; 5. The thermal conductivity of the thermally conductive silicone sheet is adjustable, and the thermal conductivity is more stable; 6. Requirement of poor workmanship of heat dissipation structure; 7. Thermally conductive silicone sheet has insulation properties (this feature requires appropriate materials to be added in the production); 8. Thermally conductive silicone sheet has the effect of shock absorption and sound absorption; 9. Thermally conductive silicone sheet has installation, Tested, reusable convenience. Disadvantages Compared with thermally conductive silicone grease, thermally conductive silicone has the following disadvantages: 1. Although the thermal conductivity is higher than that of thermally conductive silicone, the thermal resistance is also higher than that of thermally conductive silicone. 2. Thermally conductive silicone sheet with a thickness of 0.5mm or less has a complex process and relatively high thermal resistance; 3. Thermally conductive silicone grease has a larger temperature resistance range. They are thermally conductive silicone grease -60℃~300℃, thermally conductive silicone film -50℃~220 ℃; 4. Price: Thermally conductive silicone grease has been widely used, and the price is relatively low. Thermally conductive silicone sheets are mostly used in thin and small precision electronic products such as notebook computers, and the price is slightly higher.

Uses of thermally conductive silicone sheet

1, LED TV, video equipment 2, network player, household appliances, 3, mobile power LED lighting 4, backlight module, switching power supply 5, medical equipment, communication equipment 6, PC server base station

Application fields of thermal conductive silicone sheet

1. Automotive electronics industry applications such as xenon lamp ballasts, audio, battery modules, car series products, etc., can be used in thermally conductive silicone sheets. 2. The LED industry uses thermally conductive silicone sheets between the aluminum substrate and the heat sink; thermally conductive silicone The sheet is used between the aluminum substrate and the housing. 3, home appliance industry microwave oven/air conditioner (between fan motor power IC and casing)/induction cooker (between thermistor and heat sink). 4. Application of PDP/LED TV The heat conduction between function IC, image decoder IC and heat sink (housing).

5. Communication industry Heat conduction and heat dissipation between the set-top box DC-DC IC and the housing.

How to use thermally conductive silicone sheet

1. Keep the surface of the thermal silica gel clean to avoid the contamination of the thermal silica gel. The self-adhesive and sealing thermal conductivity of the contaminated thermal silica gel will deteriorate. 2. When removing the thermally conductive silicone sheet, the large-area thermally conductive silicone sheet should be grabbed from the center, and the smaller area is not required to grab the thermally conductive silicone sheet, because the uneven force of the large thermally conductive silicone sheet will cause deformation and affect Subsequent operations may even damage the silicone sheet. 3. Take the sheet in the left hand and tear off one of the release protective films with the right hand. The protective films on both sides cannot be removed at the same time to reduce the number and area of direct contact with the thermally conductive silicone sheet, and to keep the self-adhesive and thermal conductivity of the thermally conductive silicone sheet from being damaged. 4. Tear off the side of the protective film and face the radiator, first align the thermal conductive silicone sheet with the radiator. When slowly putting down the thermal silica gel sheet. Be careful to avoid air bubbles. 5. If bubbles are generated during the operation, you can pull up one end of the silicone sheet to repeat the above steps, or use a tool to gently wipe the bubbles, but the force is not too strong to avoid damage to the thermal conductive silicone sheet. 6. Tear off the other side of the protective film and put it into the radiator. Remove the one side of the protective film with a small force to avoid straining or pulling up the thermal silicone sheet. 7. After tightening or using a strong adhesive thermally conductive silicone sheet, apply a certain pressure to the radiator and store it for a period of time to ensure that the thermally conductive silicone sheet is fixed.

"Thermal conductive silicone sheet" is a kind of thermal conductive medium material synthesized by special process with silica gel as the base material and various auxiliary materials such as metal oxides. In the industry, it is also called thermal conductive silicone pad, thermal conductive silicone film, and soft. Thermally conductive pads, thermally conductive silicone gaskets, etc., are specially produced for the design of using gaps to transfer heat. They can fill the gaps and complete the heat transfer between the heating part and the heat dissipation part. At the same time, it also plays the role of insulation, shock absorption, and sealing. It can meet the design requirements of equipment miniaturization and ultra-thinness. It is extremely manufacturable and usable, and has a wide range of thicknesses. It is an excellent thermally conductive filler material.

Advantages and disadvantages of thermally conductive silicone sheet

Advantages 1. The material is softer, the compression performance is good, the thermal insulation performance is good, the thickness adjustable range is relatively large, suitable for filling the cavity, the two sides have natural viscosity, operability and maintainability; 2, the use of thermally conductive silicone sheet* The main purpose is to reduce the thermal contact resistance between the surface of the heat source and the contact surface of the heat sink. The thermally conductive silicone sheet can fill the gap of the contact surface very well; Heat transfer between the heat source and the radiator, and the installation of a thermally conductive silicone sheet between the heat source and the radiator can squeeze the air out of the contact surface; 4. With the supplement of the thermally conductive silicone sheet, the contact surface between the heat source and the radiator can be better The full contact, truly face-to-face contact. The reaction in temperature can achieve the smallest possible temperature difference; 5. The thermal conductivity of the thermally conductive silicone sheet is adjustable, and the thermal conductivity is more stable; 6. Requirement of poor workmanship of heat dissipation structure; 7. Thermally conductive silicone sheet has insulation properties (this feature requires appropriate materials to be added in the production); 8. Thermally conductive silicone sheet has the effect of shock absorption and sound absorption; 9. Thermally conductive silicone sheet has installation, Tested, reusable convenience. Disadvantages Compared with thermally conductive silicone grease, thermally conductive silicone has the following disadvantages: 1. Although the thermal conductivity is higher than that of thermally conductive silicone, the thermal resistance is also higher than that of thermally conductive silicone. 2. Thermally conductive silicone sheet with a thickness of 0.5mm or less has a complex process and relatively high thermal resistance; 3. Thermally conductive silicone grease has a larger temperature resistance range. They are thermally conductive silicone grease -60℃~300℃, thermally conductive silicone film -50℃~220 ℃; 4. Price: Thermally conductive silicone grease has been widely used, and the price is relatively low. Thermally conductive silicone sheets are mostly used in thin and small precision electronic products such as notebook computers, and the price is slightly higher.

Uses of thermally conductive silicone sheet

1, LED TV, video equipment 2, network player, household appliances, 3, mobile power LED lighting 4, backlight module, switching power supply 5, medical equipment, communication equipment 6, PC server base station

Application fields of thermal conductive silicone sheet

1. Automotive electronics industry applications such as xenon lamp ballasts, audio, battery modules, car series products, etc., can be used in thermally conductive silicone sheets. 2. The LED industry uses thermally conductive silicone sheets between the aluminum substrate and the heat sink; thermally conductive silicone The sheet is used between the aluminum substrate and the housing. 3, home appliance industry microwave oven/air conditioner (between fan motor power IC and casing)/induction cooker (between thermistor and heat sink). 4. Application of PDP/LED TV The heat conduction between function IC, image decoder IC and heat sink (housing).

5. Communication industry Heat conduction and heat dissipation between the set-top box DC-DC IC and the housing.

How to use thermally conductive silicone sheet

1. Keep the surface of the thermal silica gel clean to avoid the contamination of the thermal silica gel. The self-adhesive and sealing thermal conductivity of the contaminated thermal silica gel will deteriorate. 2. When removing the thermally conductive silicone sheet, the large-area thermally conductive silicone sheet should be grabbed from the center, and the smaller area is not required to grab the thermally conductive silicone sheet, because the uneven force of the large thermally conductive silicone sheet will cause deformation and affect Subsequent operations may even damage the silicone sheet. 3. Take the sheet in the left hand and tear off one of the release protective films with the right hand. The protective films on both sides cannot be removed at the same time to reduce the number and area of direct contact with the thermally conductive silicone sheet, and to keep the self-adhesive and thermal conductivity of the thermally conductive silicone sheet from being damaged. 4. Tear off the side of the protective film and face the radiator, first align the thermal conductive silicone sheet with the radiator. When slowly putting down the thermal silica gel sheet. Be careful to avoid air bubbles. 5. If bubbles are generated during the operation, you can pull up one end of the silicone sheet to repeat the above steps, or use a tool to gently wipe the bubbles, but the force is not too strong to avoid damage to the thermal conductive silicone sheet. 6. Tear off the other side of the protective film and put it into the radiator. Remove the one side of the protective film with a small force to avoid straining or pulling up the thermal silicone sheet. 7. After tightening or using a strong adhesive thermally conductive silicone sheet, apply a certain pressure to the radiator and store it for a period of time to ensure that the thermally conductive silicone sheet is fixed.

If you have any questions or comments, you can leave us a message and we will reply to you as soon as possible